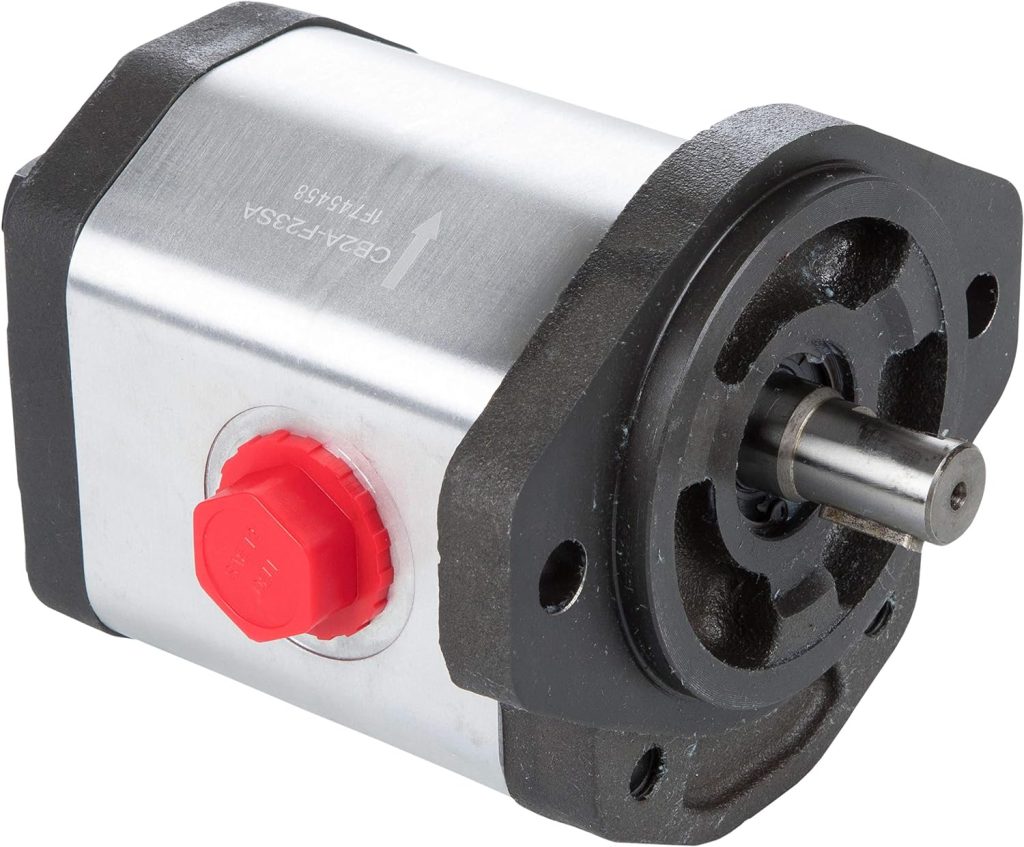

9.22 GPM Single Stage hydraulic pump

9.22 GPM single stage hydraulic pump offers efficient fluid flow for powering hydraulic systems. Its benefits include high performance, reliable operation, and suitability for applications requiring consistent hydraulic pressure. The pump’s design ensures simplicity, durability, and ease of maintenance, making it ideal for various industrial and mobile equipment where reliable hydraulic power is essential.

Hydraulic Gear stage hydraulic Pump

3600 PSI hydraulic pump

single stage hydraulic pump

| Manufacturer | RuggedMade |

| Product Dimensions | 5 x 5 x 5 inches |

Applications and Functions of Hydraulic Gear Stage Pump

Hydraulic gear stage single pumps are widely utilized across industries for their specific applications and functional capabilities:

Applications:

These pumps are commonly employed in:

Material Handling: They power hydraulic systems in forklifts, cranes, and conveyor systems, ensuring efficient movement of goods and materials.

Construction Equipment: Used in excavators, loaders, and bulldozers for lifting, digging, and moving heavy materials.

Industrial Machinery: Essential for presses, injection molding machines, and hydraulic presses, providing precise control over operations.

Agricultural Machinery: Used in tractors, combines, and sprayers for tasks such as lifting, steering, and controlling implements.

Functions:

Hydraulic Pressure Generation: They create hydraulic pressure by forcing fluid into the system, powering hydraulic cylinders and motors.

Flow Control: These pumps regulate the flow of hydraulic fluid, ensuring consistent and reliable operation of hydraulic systems.

Compact Design: Their compact size makes them suitable for installations where space is limited, such as in mobile equipment and tight industrial environments.

Durability and Reliability: Designed with robust materials, they offer long-term performance and withstand harsh operating conditions.