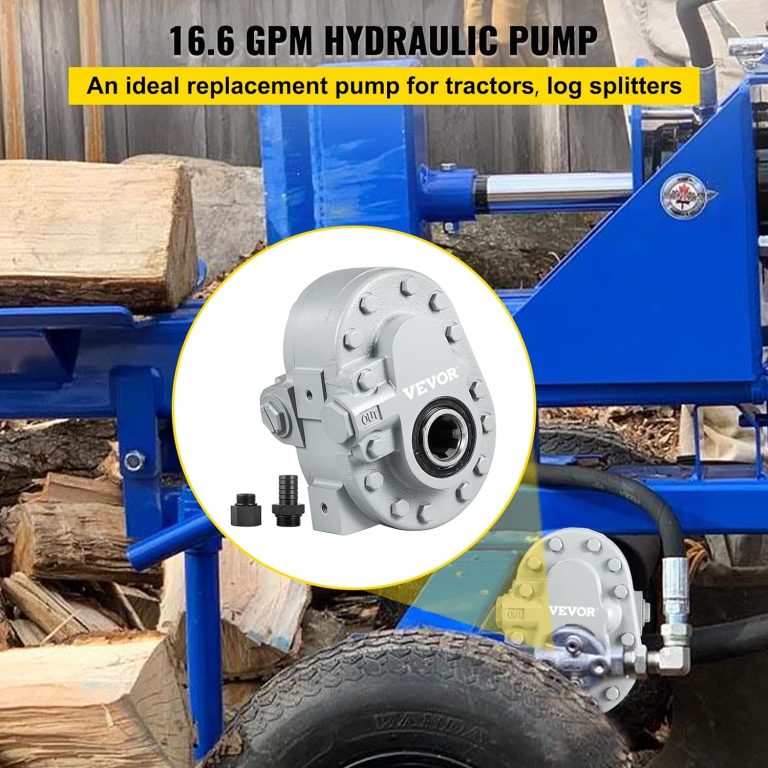

Hydraulic Pump 13 GPM Hydraulic Motor Pump

13 gpm Hydraulic pumps play a vital role in powering hydraulic systems across a wide range of industries, providing efficient and reliable hydraulic energy conversion for a variety of applications. Their design features ensure optimum performance, durability and adaptability to meet varying operational requirements.

3000PSI 2 Stage Hydraulic Pump for Log Splitter

13 gpm Hydraulic pumps

| Material: | Steel |

| Size: | 2.5cm/0.98inch |

vevot steel hydraulic pump

Types and Configurations: Hydraulic pumps are available in different types such as gear pumps, vane pumps, piston pumps (both axial and radial piston pumps) and screw pumps. Each type has distinct advantages in terms of efficiency, flow rate, pressure capability and suitability for specific applications.

Flow: The flow rate of a hydraulic pump determines how much hydraulic fluid it can deliver per unit of time. It is critical to ensuring that hydraulic actuators, such as cylinders or motors, receive enough hydraulic fluid to operate efficiently.

Pressure Rating: The pressure rating of a hydraulic pump is the maximum pressure it can produce. This rating is important in selecting a pump that can meet the pressure requirements of a hydraulic system and withstand occasional pressure spikes without failure.

Efficiency: Modern hydraulic pumps are designed for high efficiency to minimize energy loss and reduce operating costs. Improvements in efficiency often include optimizing internal clearances, improving sealing technology and reducing friction.

Durability: Hydraulic pumps are typically made of durable materials such as cast iron, steel or aluminum alloys to withstand high pressures and harsh operating conditions. They are designed to ensure longevity and reliability in industrial environments.

Control features: Some hydraulic pumps have features that control flow and pressure, such as adjustable displacement pumps or variable pumps. These features allow for precise control over the performance of the hydraulic system.

Noise and vibration: Manufacturers design hydraulic pumps to operate quietly with minimal vibration, increasing user comfort and reducing noise pollution in industrial environments.

Installation and commissioning: Hydraulic pumps are designed for easy installation and integration into hydraulic systems. They often come with standardized mounting ports and hose or pipe connections.

Maintenance: Maintenance requirements vary depending on the type and design of the pump. Many pumps are designed with accessible parts for easy inspection, repair and replacement of wear parts such as seals and bearings.

Designed for specific applications: Hydraulic pumps are designed for specific applications such as mobile machinery (e.g., construction equipment, agricultural machinery), industrial machinery (e.g., presses, machine tools), aerospace, or marine applications, each of which requires a pump with unique performance characteristics.