How does a hydraulic pump work simple?

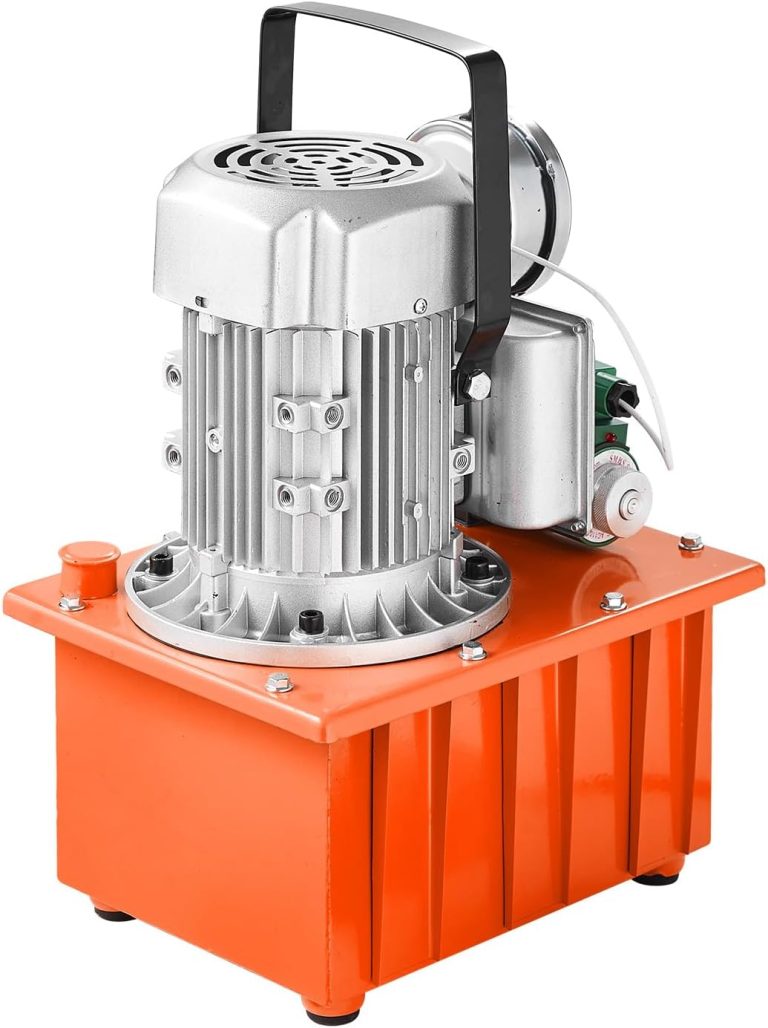

During rotation, as the space or chamber enclosed by vanes, rotor, and housing increases, a vacuum is created, and atmospheric pressure forces oil into this space, which is the inlet side of the pump. As the space or volume enclosed reduces, the liquid is forced out through the discharge ports

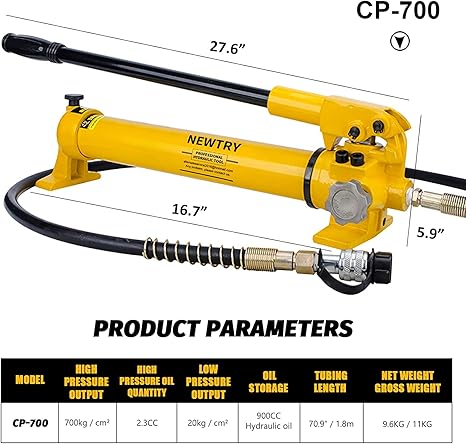

hand pump hydraulic cylinder is a device that transfers fluid from one location to another through a closed system of pipes. It operates based on the principle of fluid mechanics and Pascal’s Law, which states that pressure exerted anywhere in a confined fluid is transmitted equally in all directions throughout the fluid.

The basic working principle involves several key steps:

Fluid Intake: The pump begins by creating a vacuum or low-pressure zone at the inlet port. This allows fluid, typically oil, to be drawn into the pump from a reservoir or another part of the hydraulic system.

Fluid Compression: Once inside the pump, the mechanical components, such as gears, vanes, or pistons, pressurize the fluid. As these components move, they squeeze the fluid, increasing its pressure.

Fluid Discharge: The pressurized fluid is then pushed out of the pump through the outlet port. The pressure generated depends on the design of the pump and the force applied to compress the fluid.

Power Transmission: The high-pressure fluid is directed through hydraulic hoses and pipes to the hydraulic actuators, such as cylinders or motors, where it performs work. The pressure in the fluid creates force or torque, depending on the type of actuator, which is used to move loads or perform other tasks.

Hydraulic pumps are essential in various applications where substantial power and precise control are required, such as in construction equipment, manufacturing machinery, and aircraft systems. They are valued for their efficiency, reliability, and ability to generate high forces or torques with relatively small input power. The choice of pump type (gear, vane, piston) depends on factors like flow rate, pressure requirements, and operational conditions, ensuring optimal performance in diverse hydraulic systems.