What makes the fluid flow in a hydraulic system?

What makes the fluid flow in a hydraulic system?

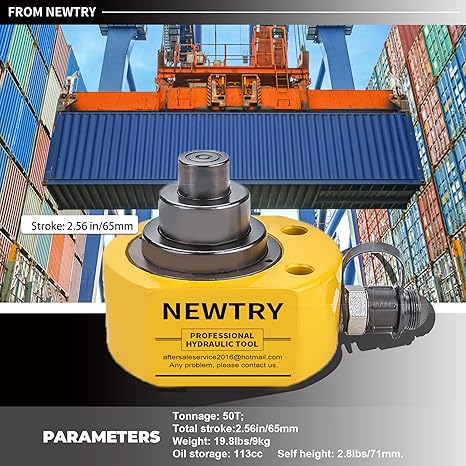

Hydraulic fluid is moved by pumps through control valves and on to mechanical actuators like hydraulic cylinders or motors, which then use the pressure to move implements such as tractor buckets, excavators, and lift cranes.

What is the use of belt driven hydraulic pumps?

Belt driven hydraulic pumps are used to power hydraulic systems in various applications, such as construction equipment, agricultural machinery, and industrial machinery. They utilize a belt connected to an engine or motor to drive the hydraulic pump. This setup allows for flexible placement and easier maintenance compared to direct-drive systems. Belt-driven pumps are particularly useful in applications where varying engine speeds are encountered, as they can maintain consistent hydraulic pressure and flow rates regardless of engine RPM. This versatility and reliability make them ideal for powering hydraulic systems in diverse operational environments.

What makes the fluid flow in abidirectional hydraulic pump?

Bidirectional hydraulic pump facilitates fluid flow in both directions due to its design and internal mechanisms. It typically includes valves or ports that can switch the direction of fluid flow depending on the operation. When the pump is activated, it pressurizes hydraulic fluid, which flows through internal passages to the desired hydraulic circuit or actuator. Reversing the direction of the pump’s rotation or adjusting valve settings allows the hydraulic fluid to flow back through the pump in the opposite direction. This bidirectional capability enables the pump to control hydraulic systems for tasks such as lifting, pushing, or rotating components in various industrial and mobile equipment applications.